The Textile Fiber Recycling Line can effectively convert cellulosic materials such as waste fabrics, cotton, cloth, wool, and textiles into high-quality recycled fibers by means of advanced sorting, crushing, cleaning, and treatment processes. The recycling line is highly automatic and saves a lot of human resources.

brief introduction of textile fiber recycling line

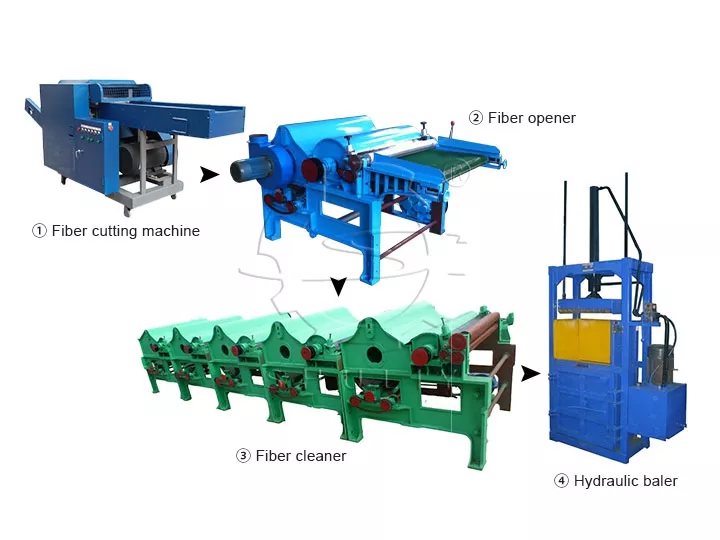

The textile fiber recycling line is an integrated system that includes the following main machines: waste fiber cutting machine, fiber opener, fiber carding machine, and vertical textile baling machine.

The process of the whole production line is coordinated and orderly. Through the synergistic action of these machines, the waste cellulose materials can be processed efficiently, thus realizing the recycling of resources.

Waste Fiber Recycling Plant workflow

The whole textile fiber recycling line needs to go through the following series of processes: fiber cutting→opening→cleaning→packing. The corresponding machines are as follows.

textile fiber cutting machine

Fiber cutters are equipped with sharp blades or knives that can effectively cut waste cellulosic raw materials into the desired length or shape. It provides suitable raw materials for subsequent processing steps, such as in the stages of pulp preparation and recycled fiber production.

The machine is equipped with two adjustable motors, two static knives, and four movable knives. The size of the final material is usually 3-15 cm, which can be adjusted according to the actual production needs.

fiber opening machine

The next raw material enters the fiber carding machine, whose main function is to untwist the cellulose raw material that was originally twisted or entangled so that it presents a certain loose state. Dispersing the fibers improves the processability of cellulose and improves the results of subsequent processes.

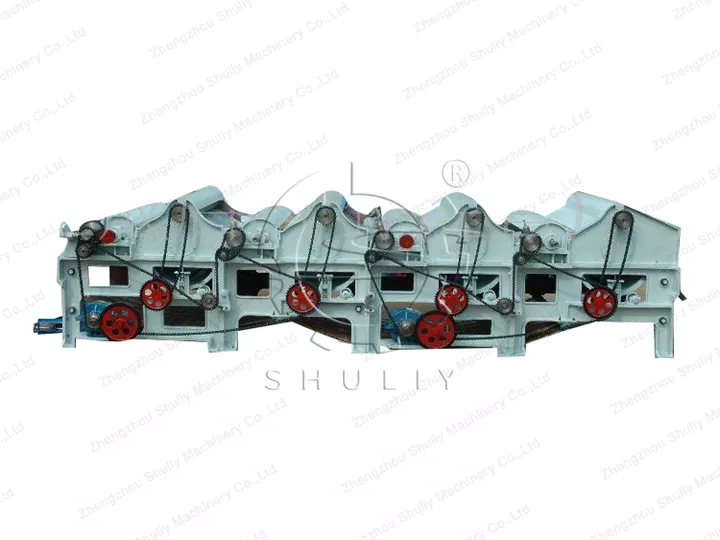

textile fiber cleaning machine

The cotton waste opener and cleaner machine break up and loosen the cellulose material to form a popcorn-like structure. This process helps to increase the surface area of the cellulose, improving the regeneration efficiency and providing a high-quality raw material for subsequent processes.

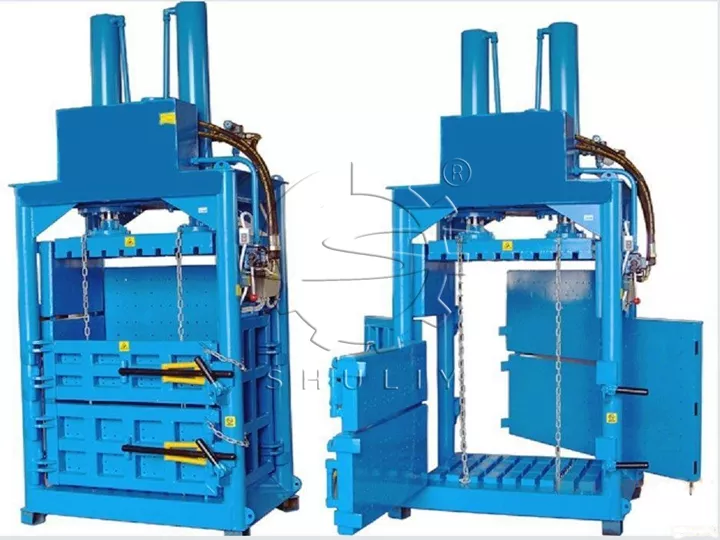

vertical hydraulic baler machine

Vertical hydraulic balers are capable of compactly and robustly baling large quantities of loose waste cellulosic materials, improving ease of transportation and storage. And it is fast, efficient, and space-saving.

benefits of Textile Fabric Cotton Recycling Machine

The textile fiber recycling line equipment has the following advantages:

- Efficient and high quality: Our waste fiber recycling equipment adopts internationally advanced technology, the huge centrifugal force generated by high-speed operation can remove impurities well, and the finished products are of good quality.

- Wide range of applications: This textile recycling equipment is suitable for recycling all kinds of waste materials, such as waste cotton, waste yarn, waste cloth, waste cloth, waste hemp, and so on.

- Energy savings: Energy consumption is typically lower during fiber recycling compared to harvesting and processing new cellulosic materials, contributing to energy savings.

- Economic benefits: Through fiber recycling, high-quality recycled fibers can be obtained, reducing production costs, simple operation, long service life, and improving economic benefits.

textile waste recycling process machine price advantage

Shuliy’s textile fiber recycling line machines have the following price advantages:

- Competitive price: Our company actively controls production costs and enables customers to obtain high-quality equipment at more attractive prices through efficient production processes and optimized management.

- Customized service: We provide customized solutions, flexibly adjusting configurations according to customer’s specific needs and budgets to ensure that customers buy the most suitable machines for their needs and avoid unnecessary waste.

- After-sales service: We are committed to providing a full range of after-sales services, including equipment installation and commissioning, training, maintenance, etc., to reduce the cost of use and improve the life of the equipment.

- Technical support: Whether it is equipment operation problems or technical difficulties, we are able to provide customers with quick solutions to ensure the normal operation of the equipment.