The Hanger Making Machine includes the steps of molding, connecting, and trimming the hangers. It has a high output of 25-40 hangers in one minute, which can meet the demand for fast and batch production. The diameter of metal wire for making hangers can be 1.8-3mm. This machine supports to make both children and adult hangers. Meanwhile, it can be customized to process various shapes and sizes, such as right-angled, butterfly-shaped hangers, shoulder-folded hangers, etc. The size range of hangers is 13-19cm.

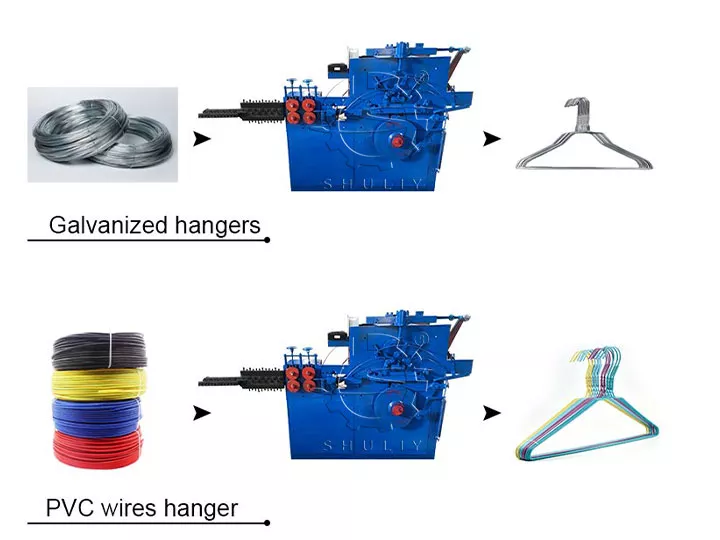

applicable materials for hanger making machine

Clothes hanger machines usually use materials such as metal or plastic for hanger production. The specific applicable raw materials mainly include:

- Metal materials: e.g. PVC coated metal wire, iron steel materials, and aluminum materials: have good corrosion resistance and are suitable for the manufacture of lightweight, easy-to-carry hangers.

- Plastic materials: one of the common raw materials for plastic coat hangers, characterized by lightness, robustness, and low cost.

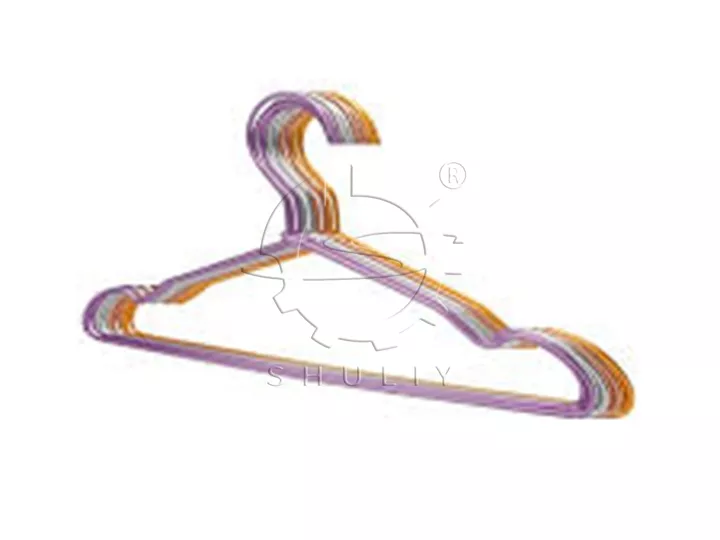

Finished hangers you can get

By using our hanger making machines, you can get a finished hanger that is strong, durable, lightweight, well-formed, and consistent. This depends on the design, raw material, and production process of the hanger. At the same time, we can help you with hanger pattern design and raw material evaluation and testing.

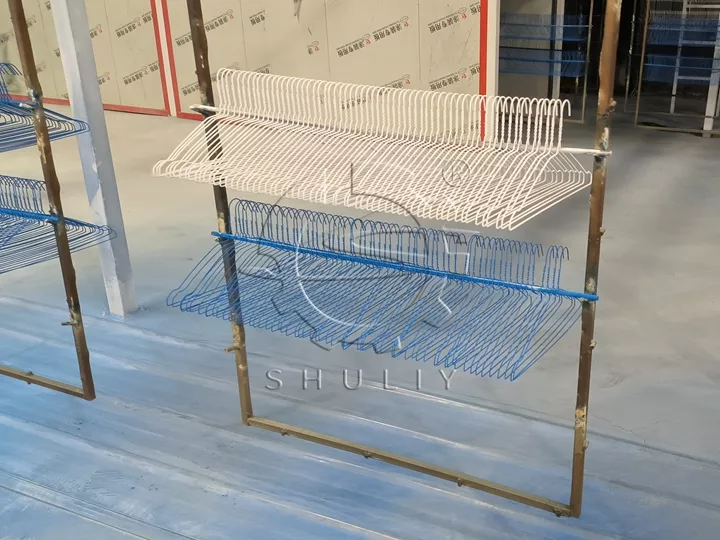

Plastic spraying equipment display

The hanger machine is equipped with plastic spraying equipment, which is mainly used to paint the surface of the hanger. Its function is to enhance the appearance quality and durability of the product.

Color customization of the hangers can be achieved so that they meet market demand and brand identity. This increases the corrosion, scratch, and fade resistance of the product surface.

Plastic spraying equipment usually features highly automated and precise control systems to ensure even and consistent coating. It improves production efficiency and provides critical support for producing high-quality coat hanger products.

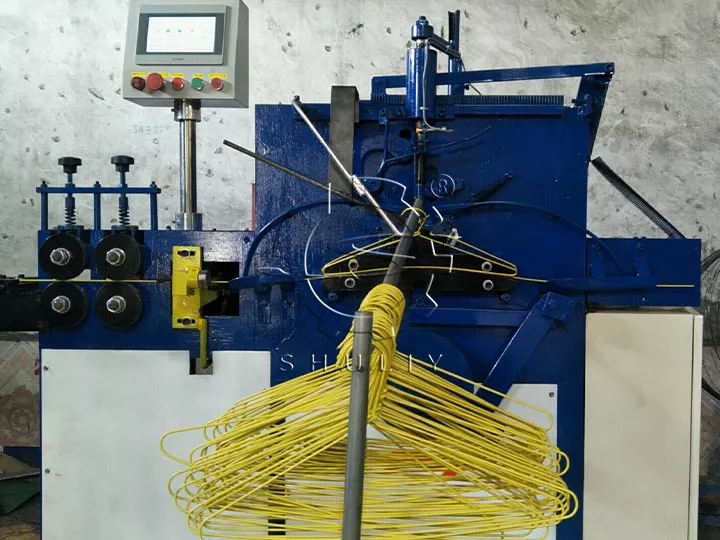

How to make a hanger?

First, the iron wire is fed through straightening and conveying wheels, which are continuously rolling to transport the wire to the forming die.

When the wire reaches the baffle, it stops. Next, the wire is shaped in the forming mold. Finally, the end of the wire is twisted and secured onto the hanger hook by a synchronous torsion bar. Remarkably, the entire process takes no more than 0.04 seconds.

why you should choose shuliy hanger machine?

At present, our hanger machine has been sold to many countries in the world. We have established a good cooperation relationship with more than 80 countries. For example, the USA, UK, Uzbekistan, Nigeria, Tunisia, India, Pakistan, Turkey, Algeria, and so on. Customers choose our hanger machine mainly because of the following advantages.

- Many years of experience: we are a manufacturer and supplier of hanger machines and invest a lot of money every year in their modernization and development.

- Customization ability: we can customize the hanger making machine according to the specific needs of customers, including production capacity, molding size, color spraying, etc., to meet the individual needs of different customers.

- Competitive price: we are committed to providing competitive prices and ensuring that our customers receive value-for-money products by continuously improving production efficiency and managing costs.

- Comprehensive service: our team provides comprehensive pre-sales consulting services, and includes training, equipment maintenance, spare parts supply, etc. We can assist our clients with factory design, calculating the factory area, drawing factory floor plans and 3D drawings, and so on.

- Efficient delivery cycle: we focus on efficient production and delivery to ensure that customers get the equipment they need in the shortest possible time, reducing waiting time.

technical parameters of automatic hanger machine

Our clothes hanger machine has an output range of 1,800 to 2,500 hangers per hour. This machine is capable of producing children’s hangers ranging from 13 to 14 inches and adult hangers ranging from 15 to 18 inches. More detailed parameters are shown below. Additionally, if you have specific requirements, we offer customized services to meet your needs.

| Capacity | 1620-1680pcs/hr |

| P.V.C coated wire | 2.8mm~3.6mm |

| Galvanized wire | 1.8mm~2.2mm |

| Motor | 2HP |

| Wire feeding stand | 2HP |

| Hanger size | 13-14cm Children / 15-19cm Adults |

| Net weight | 750KG |

| Machine size | 1800L*800W*1650Hmm |

Our factory is also equipped with a complete hanger production line, which customers can choose from according to their specific needs. Whether you need a single machine or a full set of production solutions, we can provide you with customized services. Welcome to contact us anytime for more product information and professional consultation.