The pillow filling machine is responsible for injecting precise amounts of filling material (such as fiber, cotton, or foam particles) into the pillowcase to ensure that each pillow has an even fill and high-quality comfort. This critical step ensures that pillows are produced with the consistency, comfort, and quality that the market and customers demand.

Large range of finished products on display

The raw material for a pillow filling machine is usually processed through a textile recycling machine such as a fiber opener and cleaner, and the filling range can vary depending on the model and design, processing it into many shapes and types of finished products. Finished products include pillows, cushions, pillowcases, quilts, etc.

cotton charging machine working principle

Pillow stuffing machines work by controlling the injection of filling material, injecting a precise amount of filling material evenly into the fabric product to create high-quality pillows and cushions. This automated process improves productivity and product consistency.

Supply of filling material

First, the pillow sucking machine conveys the filling material (e.g., fiber, down, memory foam, etc.) through a supply system into the bins or containers of the pillow filling machine. This process can be manual or automatic, depending on the design of the machine.

Fabric Product Positioning

The fabric product (usually a pillowcase or cushion cover) is positioned in the work area of the fiber pillow making machine, usually a table or conveyor belt.

Injection of Filling Material

When the pillow filling machine starts working, the filling head takes the filling material from the bins or containers and injects it precisely into the interior of the fabric product through the injection pipe. The amount and density of filling material injected can be adjusted as needed.

Filling uniformity detection

Some advanced pillow-making machines are equipped with detection systems that monitor the uniformity of the filling material. These systems can automatically adjust the filling process to ensure consistent filling for each product.

Finished Product and Quality Inspection

After filling, the fabric product typically undergoes a series of subsequent processes, such as sealing, sewing, or flattening, to ensure that the filling does not move or collapse. Finally, the resulting pillow or cushion is usually subjected to quality inspection to ensure that its appearance and comfort meet standards.

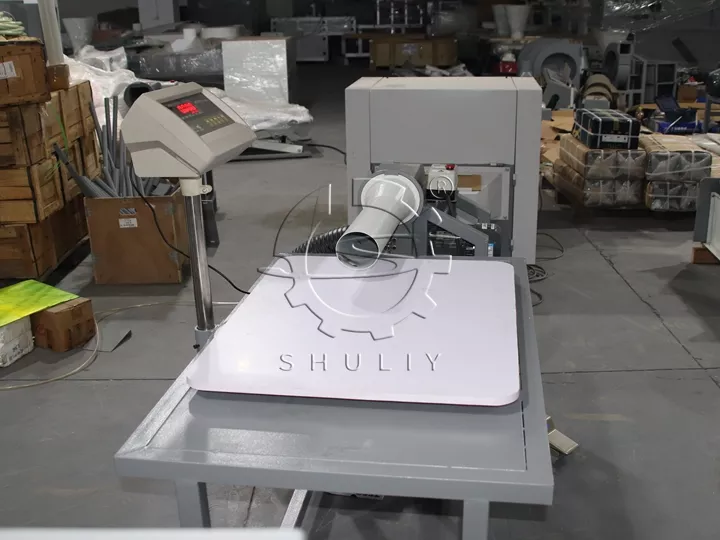

cotton Pillow making machine supporting structure

The main parts of the automatic pillow stuffing machine are the foot controller, scale, outlet, etc., of which the outlet can be adjusted in caliber according to the size of the finished product. When customers buy, they can match more than one. In addition, to improve the working efficiency and output, it can be equipped with two outlets working at the same time.

main features of fiber pillow filling machine

- Automatic cotton absorption, cotton filling function, the efficiency is 30 times of manual.

- Monitoring the distribution of filling materials ensures consistent quality for each product.

- Fills 1 pillow every 2 seconds.

- New type of foot pedal control, more uniform flushing, faster rate.

- low noise, energy consumption reduced by 30%, simple operation, production safety.

- Adjustable injection speed and pressure control ensure that the filling material is evenly distributed inside the fabric product.

pillow stuffing machine specifications

The pillow filling machine is easy to operate and requires only one or two operators. It supports automatic feeding and the operator only needs to place the raw material on the conveyor belt. Compared with similar products, this machine has the advantage of saving material. Some of the main parameters are as follows:

| Model | SL-100 | SL-200 |

| Capacity | 100-150KG/H | 100-200KG/H |

| Air pressure | 8.2~15.5m³/min | 8.2~15.5m³/min |

| Voltage | 380v/50hz | 380v/50hz |

| Power | 2.2KW | 4KW |

| Dimensions | 600×700×800(mm) | 600×700×900(mm) |

| Weight | 100KG | 120KG |

We can customize the fiber pillow making machine according to the different needs of customers for the shape of the finished product as well as the size, etc. Please let us know what you need and feel free to contact us!