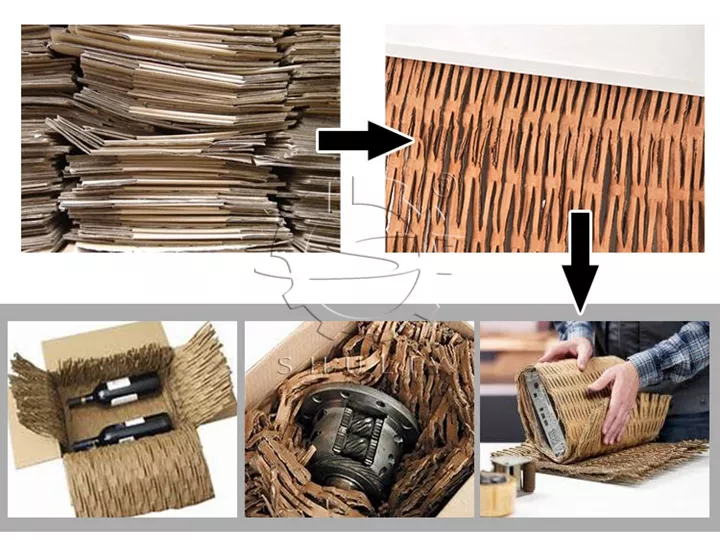

The cardboard shredder machine is an environmentally friendly and efficient cardboard processing equipment that cuts waste corrugated cartons, cardboard, and other packaging materials into reusable cushioning packaging materials.

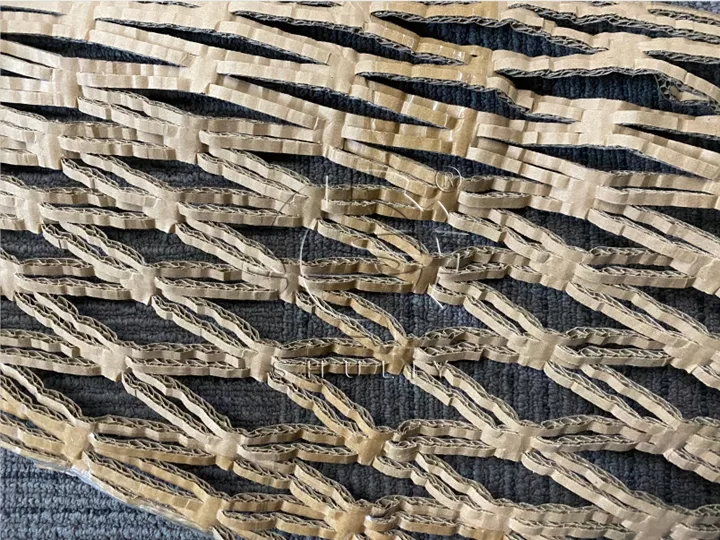

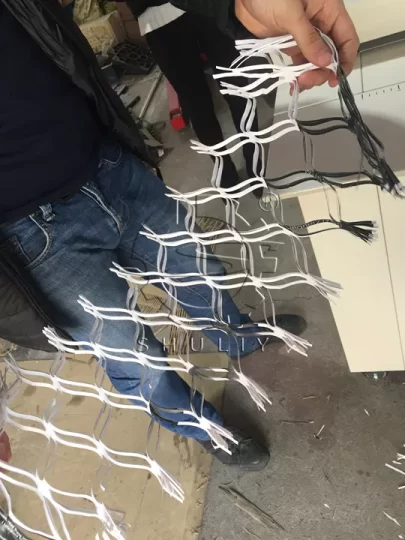

Through the intelligent cutting process, these cartons, which originally need to be scrapped and disposed of, can be quickly transformed into environmentally friendly, non-polluting packaging fillers such as flat nets, spacers, mesh cushioning pads, paper strips, and so on.

It effectively reduces the packaging cost of enterprises and the reliance on non-degradable materials such as foam, providing a green, low-carbon, and sustainable solution for the logistics, manufacturing, and packaging industries.

Cardboard shredder machine applications

Cardboard shredders have a wide range of applications in various industries and settings due to their ability to efficiently process and manage cardboard waste. Some common applications of cardboard box shredders include:

- Packaging and shipping centers: for processing recycled cartons, generating reusable cushioning materials and reducing the cost of purchasing new packaging materials.

- Manufacturing plants: for cushioning packaging filling of precision instruments, electronic products, ceramics, glass, furniture and other products.

- Recycling center: initial processing of cardboard waste, easy to pack and transport to paper mills for secondary recycling of paper.

- Office environment: daily carton waste can be handled inside the office, realizing environmentally friendly office and resource reuse.

- Crafts and creative field: in art creation, exhibition sets, as paper art materials for re-creation.

The versatility of cardboard shredders makes them valuable tools in waste management, recycling, and even creative endeavors, contributing to more sustainable practices and reduced waste volumes.

Principle of machine structure and operation

This machine is driven by the motor through the chain belt, gear drive, drive the knife shaft interaction, to complete the machine cutting task. Therefore, it must be operated by the operating regulations and standardized operation. To avoid accidents.

In a well-ventilated place, connect the placed machine to the power supply, turn on the power switch, and trigger the main switch in the clockwise direction.

The machine will then start to run and the material will be fed into the feeder according to the required size. Material width greater than 425mm will be cut off automatically.

cardboard shredding machine Main accessories

The knives of the machine as well as the molds can be customized according to the customer’s needs. In addition, different plugs can be configured according to different countries.

paperboard Shredder machine technical parameters

Shuliy produces two models of cardboard box shredder for packaging material, some of its main technical parameters are as follows:

| Model No. | SL-325 | SL-425 |

| Width of cutting the material | 325mm | 425mm |

| Thickness of the input | 20mm | 20mm |

| Shredding shape | 5×60mm (or 5mm bar) | 5×100mm(or 5mm bar or 3mm bar) |

| Thickness of shredding | 3-5 layers corrugated (20-40 pieces A4/70g paper) | 5-7 layers corrugated (20-70 pieces A4/70g paper) |

| Speed of shredding | 12m/min | 12m/min |

| Noise | 60DB | 60DB |

| Voltage | 220v,50hz | 380v,50hz |

| Power | 1.5kw | 2.2kw |

| Machine size (L*W*H) after package | 670*490*1030 mm | 630*830*1260mm |

| Gross weight | 116kg | 200kg |

features of cardboard paper shredder

- Wide range of uses: adapt to the packaging needs of multiple industries, covering electronics, ceramics, instrumentation, furniture and other types of products for transportation protection.

- Turning waste into treasure: it can deal with all kinds of waste or unqualified cartons and cardboards, including materials with printing and irregular shapes.

- Environmental protection and energy saving: using paper material instead of non-degradable substances such as foam, in line with national environmental policy requirements.

- Efficient operation: processing speed of up to 12 meters per minute, meeting the efficient needs of small and medium-sized factories or shipping points.

- Dual models: two cutting widths of 325mm and 425mm are available to flexibly adapt to different operating scenarios.

- Sturdy and durable structure: the equipment is made of high-strength materials, stable performance, easy to clean and maintain.

- Cost-effective: compared with similar imported products, the price of the whole machine is more than 30% lower, the price of spare parts can save up to 50%, and the after-sales service response is faster.

Precautions for use

- Do not wear gloves when working.

- Do not put your hand into the paper feeder when working.

- Do not approach the machine with long hair, sashes, ties, scarves, or other types of clothing.

- Sticky and variable thread materials should not be processed on the machine.

- Don’t let hard objects such as packing nails be brought into the feeding opening to avoid destroying the blades.

Successful cases

Due to the compactness and convenience of the machine and the practicality of the finished product, it is popular in many countries.

Our cardboard shredder machines have been exported to the United Arab Emirates, Ireland, Australia, the Philippines, South Korea, Lebanon, Malaysia, Saudi Arabia, Mexico, Singapore, Indonesia, Turkey, Peru, and many other countries.

The difference between it and the waste paper crushing and grinding machine is that the finished product can be processed and used directly as packaging material, while the finished product after the crusher still needs to be processed by the paper pulp machine, egg tray mold for the recycling machine, and other machines before use.

If you want to know more about these cardboard paper recycling machines and their processes, please feel free to contact us!